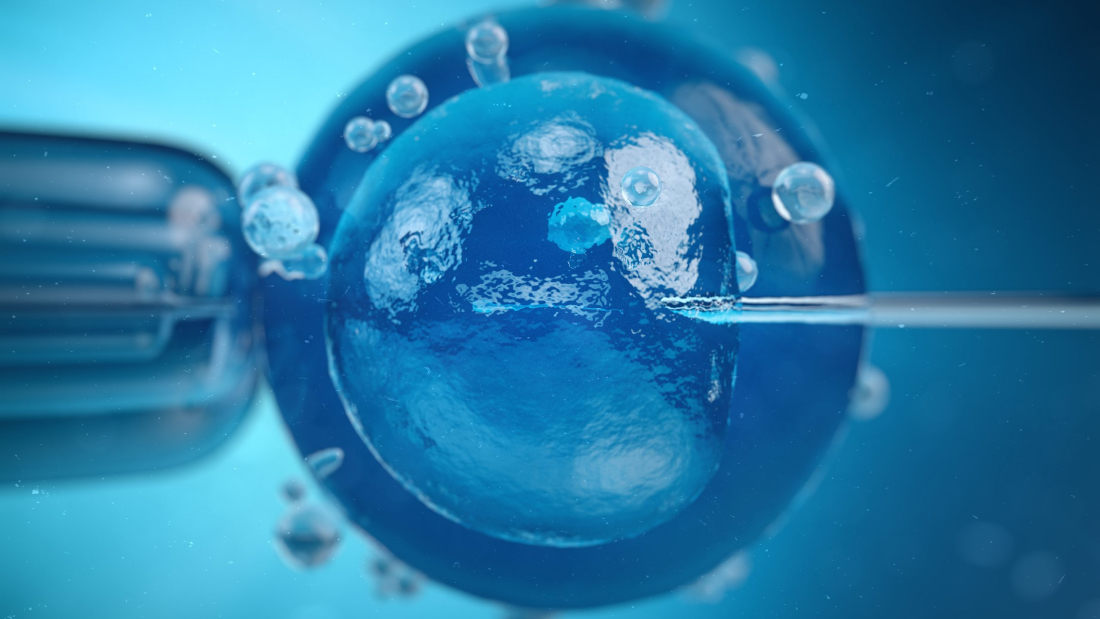

Scientists at The University of Nottingham have developed a new substance that could simplify the manufacture of cell therapy in the world of regenerative medicine.

Cell therapy is an exciting and rapidly developing area of medicine in which stem cells have the potential to repair human tissue and maintain organ function in chronic disease and age-related illnesses.

But a major problem with translating current successful research into actual products and treatments is how to mass-produce such a complex living material.

There are two distinct phases in the production of stem cell products; proliferation (making enough cells to form large tissue) and differentiation (turning the basic stem cells into functional cells). The material environment required for these two phases is different, and up to now, a single substance that does both jobs has not been available.

Now, a multi-disciplinary team of researchers at Nottingham has created a new stem cell micro-environment that they have found allows both the self-renewal of cells and their evolution into cardiomyocyte (heart) cells. The material is a hydrogel containing two polymers – an alginate-rich environment, which allows the proliferation of cells with a simple chemical switch to render the environment collagen-rich when the cell population is large enough, and…[inster 2nd polymer information]. This change triggers the next stage of cellular growth when cells develop a specific purpose.

Kevin Shakesheff, the Professor of Advanced Drug Delivery and Tissue Engineering, said, “Our new combination of hydrogels is a first. It allows dense tissue structures to be produced from human pluripotent stem cells (HPSC) in a single-step process never achieved before. The discovery has important implications for the future of manufacturing in regenerative medicine. This field of healthcare is a major priority for the UK and we are seeing increasing investment in future manufacturing processes to ensure we are ready to deliver real treatments to patients when HPSC products and treatments go to trial and become standard.”

Read full story here

Source: University of Nottingham

Brought to you by Fomat Medical

Add a Comment